Welding is a common and important metal processing method that melts and joins metal materials together by means of high temperatures. However, the deformation of weldments during the welding process has always been a challenge. In particular, bending and compression of weldments may have a significant impact on their strength and serviceability. In this paper, we will discuss the causes of bending and flattening of weldments, analyze their effects, and provide solutions.

Bending causes and effects

Bending due to thermal stress.

During the welding process, high temperatures cause localized thermal expansion of the weldment, resulting in thermal stress. When the weldment cools down, temperature differences occur in different parts, which can cause bending. In addition, the material of the weldment will also have an effect on the degree of bending. Different types of metal materials have different coefficients of thermal expansion, so inconsistent thermal stresses may occur during the welding process, causing the weldment to buckle. Buckling of weldments negatively affects their structural strength and stability. Buckling may lead to stress concentrations in the vicinity of the weld point, which increases the risk of deterioration, fracture and deformation. In addition, bending may lead to poor fit of the weldment to other components, affecting the overall assembly and function in use.

Flattening due to stress concentrations;

In addition to bending, weldments can also suffer from flattening. This problem is usually caused by localized stress concentrations at welded joints. Factors such as the geometry of the welded joint, the mechanics of the welding process, and the quality of the weld can affect the strength and freedom of the welded joint. Compression may result in the loss of structural integrity of the weldment and its inability to withstand the expected loads. In some applications, such as bridges, ships and aircraft structures, flattening of weldments may pose a serious threat to overall safety.

Solutions

In order to avoid bending and flattening problems of welded parts, here are some possible solutions:

Selection of the appropriate welding method: Different welding methods have different effects on the deformation of the weldment. Considering the use of a welding method that is suitable for a particular application can minimize the occurrence of deformation problems.

Control temperature variations during the welding process: By controlling parameters such as welding speed, welding temperature and preheating, thermal stresses and temperature differences can be reduced, thus reducing bending and flattening of the welded part.

Optimize the design of the welded structure: By considering the structural and material properties of the weldment at the design stage, the deformation problem during the welding process can be mitigated. Choosing the right shape and number of welded joints, as well as increasing the stiffness of the structure, can help to minimize bending and flattening of the weldment.

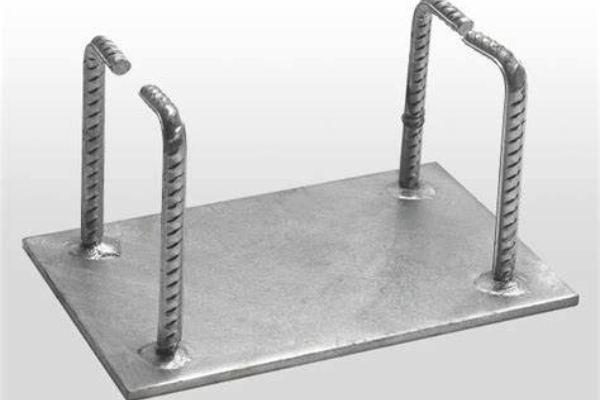

Use of Compensating Techniques: The use of compensating techniques during the welding process can reduce the deformation of the weldment. By adding temporary supports, using welding restraints, etc., the movement of the weldment can be limited and its shape can be kept stable.

Conclusion

Buckling and flattening problems of weldments have a significant impact on their structural strength and serviceability. Understanding the causes and effects of deformation problems, as well as adopting appropriate solutions, are key to ensuring the quality and reliability of weldments. By selecting appropriate welding methods, controlling welding temperatures, optimizing structural design and using compensating techniques, we can minimize the occurrence of weldment deformation problems and improve the quality and sustainability of weldments.