Welding is a common joining technique used in modern manufacturing processes. The quality of welded parts is directly related to the reliability and safety of the workpiece. Among them, the hardness of weldments is an important performance index. In this paper, we will discuss the factors affecting the hardness of weldments, test methods and measures to improve the hardness of weldments.

Factors affecting the hardness of weldments

The hardness of weldments is affected by many factors. The following is a list of some of the main factors:

Welding material selection: the hardness of the welding material has an important impact on the hardness of the weldment. Selection of welding materials with similar hardness can reduce the hardness difference and improve the hardness of the weldment.

Welding process parameters: the parameter settings in the welding process, such as welding current, welding speed, etc., will have an impact on the hardness of the weldment. Reasonable selection and control of these parameters can make the hardness of the weldment reach the desired level.

Welding heat input: welding heat input refers to the heat transferred to the weldment during the welding process. Too high or too low welding heat input will lead to a reduction in the hardness of the weldment. Therefore, reasonable control of welding heat input is the key to improve the hardness of weldments.

Test methods for hardness of welded parts

In order to assess the hardness of a welded part, common test methods include:

Hardness test: By performing indentation test on the weldment, the diameter of the indentation or the depth of the indentation is measured, and then the hardness value is deduced. Commonly used hardness test methods are Brinell hardness test, Rockwell hardness test and so on.

Organization observation: through the weldments for metallographic microscope observation, you can analyze the weldments grain size, grain boundary distribution and other organizational characteristics, so as to indirectly assess the hardness of the weldments.

Measures to improve the hardness of weldments

In order to improve the hardness of weldments, we can take the following measures:

Selection of suitable welding materials: as mentioned earlier, the choice of similar hardness of the welding material can reduce the hardness difference and improve the hardness of weldments.

Optimize the welding process parameters: By reasonably selecting and adjusting the welding process parameters, such as welding current, welding speed, etc., the heat input in the welding process can be controlled to improve the hardness of the weldment.

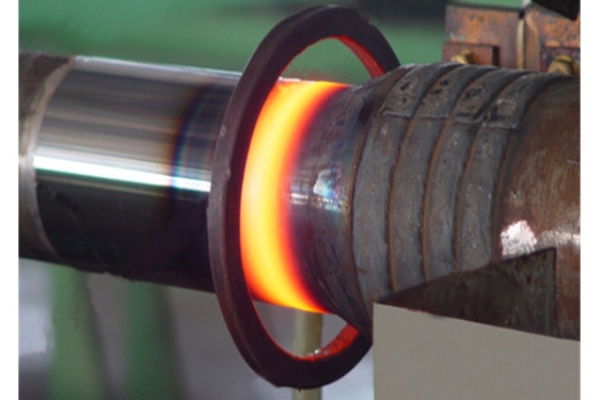

Appropriate heat treatment: through heat treatment, you can change the organizational structure of the weldment, improve the hardness of the weldment. Commonly used heat treatment methods are tempering, quenching and so on.

Conclusion

The hardness of welded parts is an important indicator for assessing their quality and reliability. The selection of the welding material, the optimization of the welding process parameters and the appropriate heat treatment can positively influence the hardness of the welded part. Only with proper selection and control, the hardness of weldments can reach the desired level, thus ensuring the safety and reliability of the workpiece. Through continuous research and practice, we can further improve the hardness of weldments and promote the development of welding technology.