Mechanical property testing is a crucial research work in the field of materials science and engineering. And in the process of material evaluation, the lower yield strength is an important index, which reflects the strength and toughness of the material. In this paper, we will discuss the definition of the lower yield strength, the test method and its significance in engineering practice.

Definition of Lower Yield Strength

Lower yield strength is the point at which a material begins to deform nonlinearly after exceeding the linear elasticity stage in the tensile or compressive process. It marks the point at which the material begins to deform plastically and increases gradually with continued increase in loading.

Test Methods for Lower Yield Strength

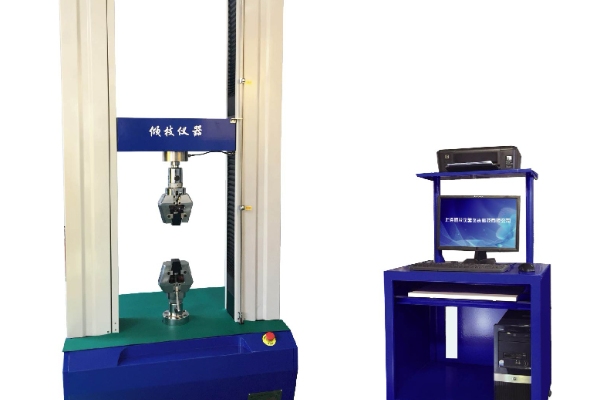

Testing for lower yield strength is usually performed by tensile testing. In a tensile test, a standard specimen is loaded until a significant deformation occurs. The lower yield strength is determined from the stress-strain curve of the material, and the bending point on the curve is the lower yield strength.

Significance of Lower Yield Strength

Lower yield strength has important significance in engineering practice. First of all, it provides an assessment of the reliability and stability of a material under normal conditions of use. By testing the lower yield strength, engineers can determine whether a material is suitable for a particular application, thus ensuring the safety of the design. Secondly, the lower yield strength also helps engineers understand the plasticity of a material. Under normal operating conditions, materials undergo a variety of stress and strain changes, and a material's plasticity is a key factor in its ability to adapt to these changes. By testing the Lower Yield Strength, engineers can assess the plasticity of a material to ensure that it will not deform or break excessively in actual use.

Lower yield strength is the point at which a material begins to deform nonlinearly in tension or compression after it has passed the linear elastic stage. It marks the point at which the material begins to deform plastically and increases gradually as loading continues.

Lower Yield Strength

Test Methods for Lower Yield Strength

Testing of the lower yield strength is usually carried out by tensile testing. In a tensile test, a standard specimen is loaded until significant deformation occurs. The lower yield strength is determined from the stress-strain curve of the material, and the bend point on the curve is the lower yield strength.

Significance of Lower Yield Strength

Lower yield strength has important significance in engineering practice. First of all, it provides an assessment of the reliability and stability of a material under normal conditions of use. By testing the lower yield strength, engineers can determine whether a material is suitable for a particular application, thus ensuring the safety of the design. Secondly, the lower yield strength also helps engineers understand the plasticity of a material. Under normal operating conditions, materials undergo a variety of stress and strain changes, and a material's plasticity is a key factor in its ability to adapt to these changes. By testing the Lower Yield Strength, engineers can assess the plasticity of a material to ensure that it will not deform or break excessively in actual use.

Lower Yield Strength

Related Research and Case Studies

Numerous studies and case studies have shown that a material's lower yield strength is closely related to its functional performance. For example, in the aerospace industry, titanium alloys are widely used to manufacture high-strength parts. By studying the lower yield strength of different titanium alloys, scientists are able to select the most suitable material for a particular aircraft design and usage scenario, ensuring that it is able to withstand the stresses of complex environments such as high temperatures and pressures. In addition, in the field of construction engineering, the lower yield strength of concrete is one of the most important indicators for determining the structural safety of buildings. By testing the lower yield strength of different ratios of concrete, engineers can determine the right concrete formulation to ensure that buildings have better resistance to earthquakes or other natural disasters.

Conclusion

Lower yield strength is a key test metric as far as mechanical property testing is concerned. It not only provides engineers with an important basis for assessing the performance and reliability of materials, but also has a profound impact on the plasticity of materials. Through scientific research and practical case studies, we can further recognize the importance of lower yield strength in different fields. Therefore, we should always pay attention to and effectively utilize the key parameter of lower yield strength in material selection and engineering design to ensure the safety and reliability of materials and structures.